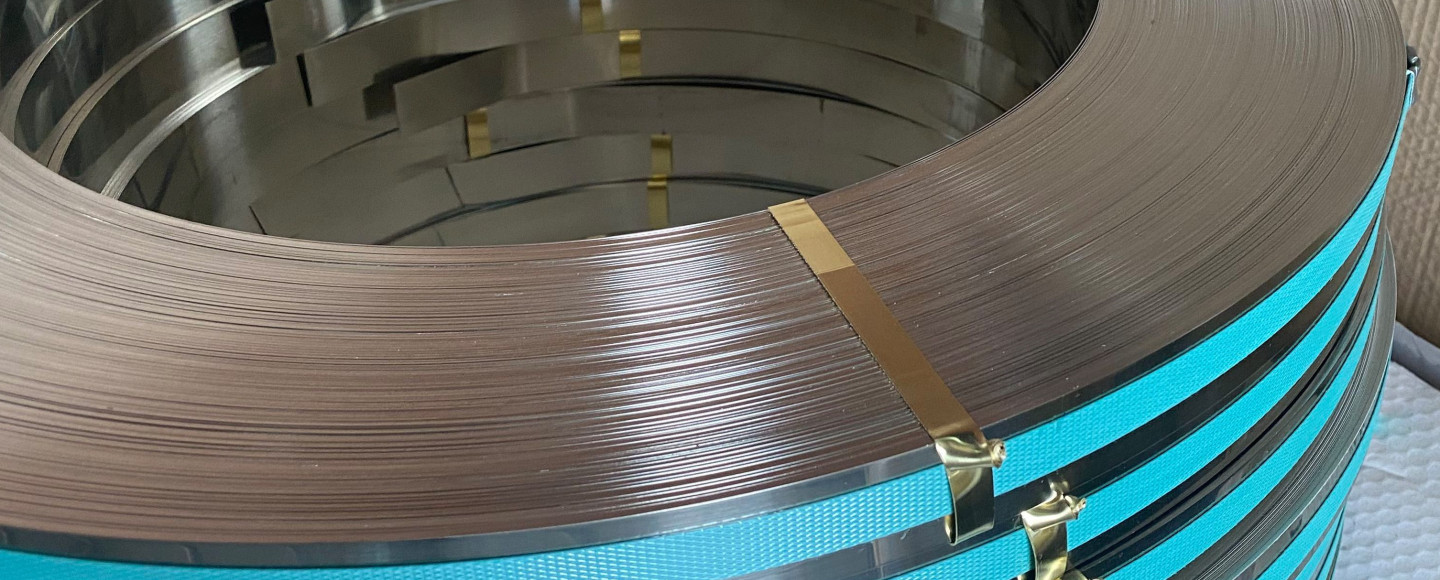

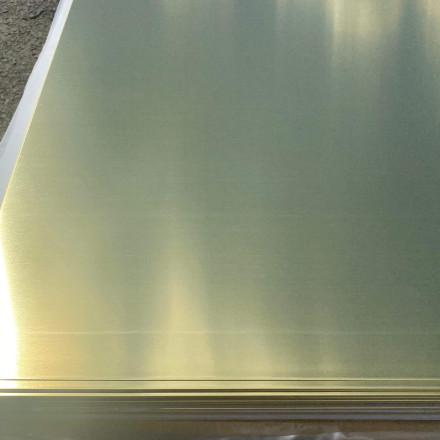

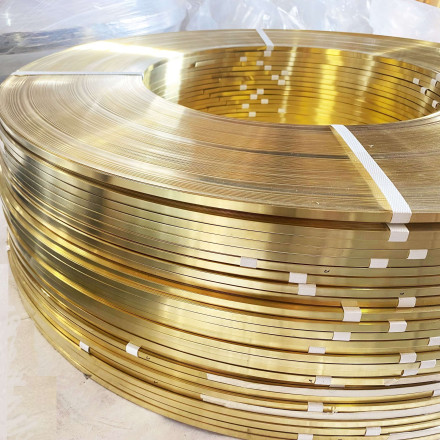

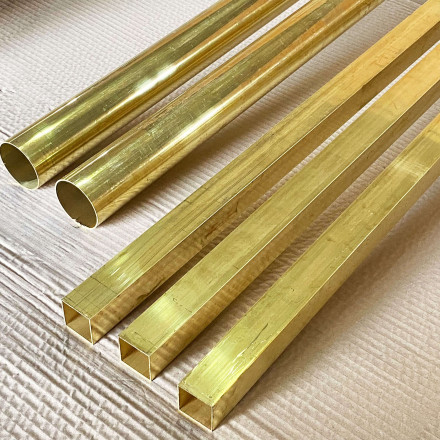

Copper-nickel strip

Copper-nickel strip in the assortment: CuNi12Zn24, CuNi18Zn20, CuNi19

Characteristics

- Alloys:

- CuNi12Zn24, CuNi18Zn20, CuNi19

- Thicnkness, mm:

- 0,2-4

- Width, mm:

- 6-350

- Price:

- upon request

Опис

Volyn' Biznes Resurs offers CuNi strips according to the individual requirements of the client: the inner diameter of the coil, the outer diameter and the weight of the coil.

CuNi12Zn24 alloy - nickel content - 12%, zinc - 24%, copper - the rest.

CuNi18Zn20 alloy - nickel content - 18%, zinc - 20%, copper - the rest.

CuNi10Zn27 alloy - nickel content - 10%, zinc - 27%, copper - the rest.

CuNi19 alloy - nickel content - 19%, copper - the rest.

The products are manufacturer in accordance with standard EN 1652 "Copper and copper alloys - Plate, sheet, strip and circles for general purposes".

VBR offers copper-nickel strips in soft, half-hard and hard state according to EN 1652. Each state provides certain characteristics for strips: hardness, tensile strength and elongation.

Hardness - is the value of material hardness. The measurement is carried out according to the Vickers method: determining the hardness of the metal by the size of the impression left by a diamond tip in the form of a quadrangular pyramid, which is pressed into the surface under the influence of the load. It is defined in units of HV.

Tensile strength - that is, temporary resistance - a measurement of the load corresponding to the greatest effort that precedes the destruction of the sample. It is measured in N/mm² (MPa).

Elongation - that is, relative elongation - is a value that shows the percentage by which a material is elongated before it breaks. This indicator is especially important for sheets used for deep drawing. It is measured in %.

According to EN 1652 «Copper and copper alloys – Plate, Sheet, strip and circles for general purposes» offers copper-nickel strips of alloys Cu-ETP, Cu-DHP, Cu-DLP, Cu-OF, Cu-FRTP and Cu-HCP with the following characteristics:

Elongation

| Soft state | Half-hard state | Hard state | Espesially the hard state | |||||

|---|---|---|---|---|---|---|---|---|

| for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | |

| CuNi12Zn24 | мін. 35 % | мін. 45% | мін. 8% | мін. 15 % | - | мін. 8% | - | - |

| CuNi18Zn20 | мін. 27% | мін. 37% | мін. 9% | мін. 18% | мін. 3% | - | - | - |

| CuNi19 | мін. 22% | мін. 22% | - | - | мін. 2,5% | мін. 2,5% | - | - |

| CuNi10Zn27 | мін. 35% | мін. 45% | мін. 8% | мін. 15% | - | мін. 8% | - | - |

Tensile strength

| Soft state | Half-hard state | Hard state | Espesially the hard state | |

|---|---|---|---|---|

| CuNi12Zn24 | R360-R430 | R430-R510 | R490-R580 | R550-R640 |

| CuNi18Zn20 | R380-R450 | R450-R520 | R500-R590 | R580-R670 |

| CuNi19 | мін. R290 | - | мін. R390 | - |

| CuNi10Zn27 | R360-R430 | R430-R510 | R490-R580 | R550-R640 |

Hardness

| Soft state | Half-hard state | Hard state | Espesially the hard state | |

|---|---|---|---|---|

| CuNi12Zn24 | 80-110 HV | 110-150 HV | 150-180 HV | 170-200 HV |

| CuNi18Zn20 | 85-115 HV | 115+160 HV | 160-190 HV | 180-210 HV |

| CuNi19 | 85-115 HV | 115-160 HV | 160-190 HV | 180-210 HV |

| CuNi10Zn27 | 80-110 HV | 110-150 HV | 150-180 HV | 170-200 HV |

Would you like to place an order?

Send a request and our manager will contact you soon

-440x440.jpg)