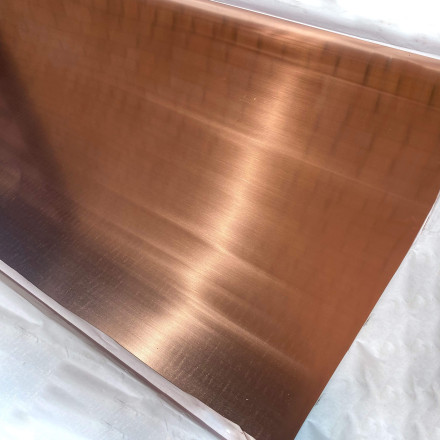

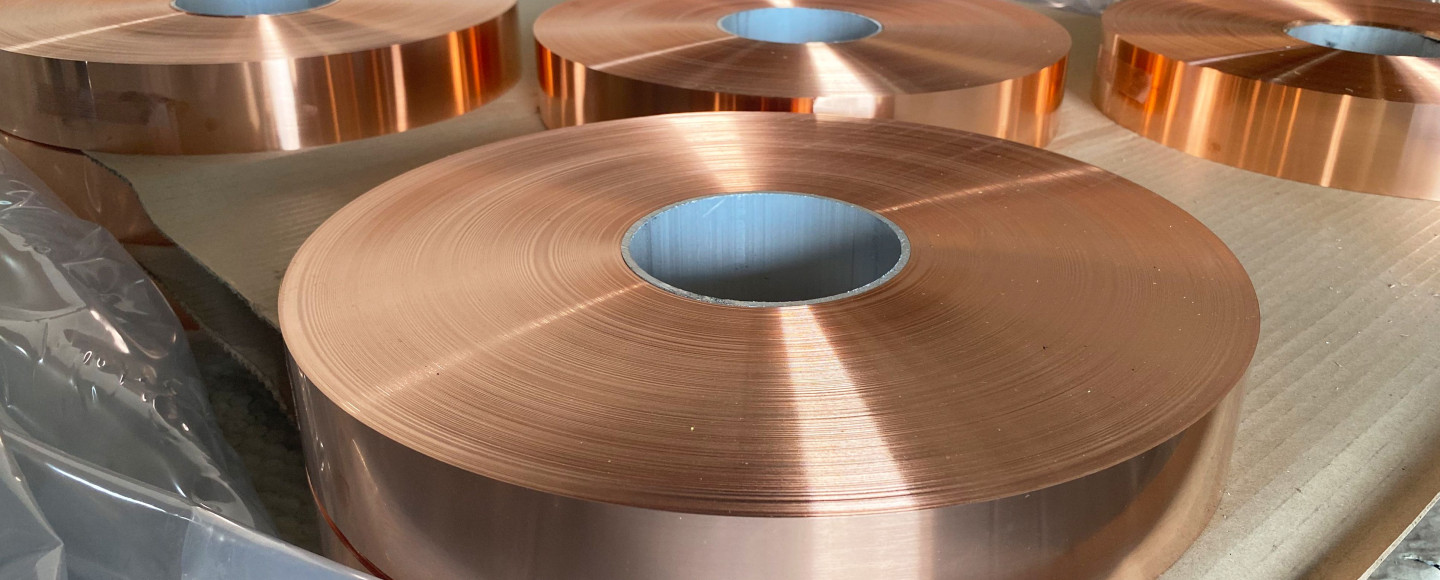

Copper strip

Copper strip in assortment: Cu-ETP, Cu-DHP

Characteristics

- Alloys:

- Cu-ETP, Cu-DHP, Cu-DLP, Cu-OF, Cu-FRTP and Cu-HCP

- Thickness, mm:

- 0,045-15

- Width, mm:

- 10-1000

- Temper:

- soft, half-hard, hard

- Price:

- upon request

Опис

Volyn' Biznes Resurs has the possibility of supplying brass strip according to the individual requirements of the client: the inner diameter of the coil, the outer diameter and the weight of the coil.

Cu-ETP is a copper alloy that contains a small amount of oxygen but no phosphorus and is therefore best suited for use in the electrical industry. This alloy has the highest electrical conductivity. Copper content - 99.90%.

Cu-DHP is a copper alloy that deoxidizes with the addition of phosphorus, that is, there is no free oxygen in copper, as a result, the electrical conductivity of this variety drops slightly. On the other hand, this type of copper is easy to weld and solder due to the lack of oxygen. Cu-DHP is also resistant to hydrogen embrittlement. Copper content - 99.90%.

Cu-DLP is deoxidized oxygen-free copper with low residual phosphorus content. It combines very good formability and bonding properties. Conductivity is reduced but higher than Cu-DHP due to low phosphorus content. Copper content - 99.90%.

Cu-OF is a highly conductive oxygen-free copper with a minimum copper content of 99.95%. It offers the benefits of both ETP electrolytic copper and phosphorus deoxidized copper. The high purity and display of deoxidizers provide 100% IACS electrical conductivity, as well as the appearance of water embrittlement. Cu-OF has very good brazing and welding properties, unlike Cu-ETP.

Cu-FRTP is a copper alloy obtained by electrolytic refining, electrolytic mining, chemical refining or fire refining. which does not contain arsenic. Does not have high electrical conductivity. The copper content is not less than 99.85%.

Cu-HCP is a copper alloy with a low residual phosphorus content, deoxidized copper. It has very high electrical and thermal conductivity, excellent soldering properties, as well as resistance to hydrogen. It is characterized by excellent hot cold forming properties, as well as good resistance to corrosion in water and especially in the atmosphere (including industrial atmosphere).

The products are manufactured in accordance with European standards: EN 1652 "Copper and copper alloys - Plate, sheet, strip and circles for general purposes" EN 13599 "Copper and copper alloys - Copper plate, sheet and strip for electrical purposes".

VBR offers copper strips in soft, half-hard and hard state according to EN 1652. Each state provides certain characteristics for strips: hardness, tensile strength and elongation.

Hardness - is the value of material hardness. The measurement is carried out according to the Vickers method: determining the hardness of the metal by the size of the impression left by a diamond tip in the form of a quadrangular pyramid, which is pressed into the surface under the influence of the load. It is defined in units of HV.

Tensile strength - that is, temporary resistance - a measurement of the load corresponding to the greatest effort that precedes the destruction of the sample. It is measured in N/mm² (MPa).

Elongation - that is, relative elongation - is a value that shows the percentage by which a material is elongated before it breaks. This indicator is especially important for sheets used for deep drawing. It is measured in %.

According to EN 1652 «Copper and copper alloys – Plate, Sheet, strip and circles for general purposes» offers copper strips of alloys Cu-ETP, Cu-DHP, Cu-DLP, Cu-OF, Cu-FRTP and Cu-HCP with the following characteristics:

Elongation

| Soft state | Half-hard state | Hard state | Espesially the hard state | |||||

|---|---|---|---|---|---|---|---|---|

| for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | for thicknesses up to and including 2,5 mm | for thicknesses over 2,5 mm | |

| Cu-ETP | - | мін. 42% | мін. 33% | мін. 42% | мін. 8% | мін. 15% | мін. 4% | мін. 6% |

| Cu-HCP | мін. 33% | мін. 42% | мін. 8% | мін.15% | мін. 4% | мін. 6% | мін. 2% | - |

| Cu-FRTP | - | мін. 42% | мін. 33% | мін. 42% | мін. 8% | мін. 15% | мін. 4% | мін. 6% |

| Cu-OF | - | мін. 42% | мін. 33% | мін. 42% | мін. 8% | мін. 15% | мін. 4% | мін. 6% |

| Cu-DLP | - | мін. 42% | мін. 33% | мін. 42% | мін. 8% | мін. 15% | мін. 4% | мін. 6% |

| Cu-DHP | - | мін. 42 % | мін. 33% | мін. 42% | мін. 8% | мін. 15% | мін. 4% | мін. 6% |

Tensile strength

| Soft state | Half-hard state | Hard state | Espesially the hard state | |

|---|---|---|---|---|

| Cu-ETP | R200-R260 | R240-R300 | R290-R360 | мін. R360 |

| Cu-HCP | R200-R260 | R240-R300 | R290-R360 | мін. R360 |

| Cu-FRTP | R200-R260 | R240-R300 | R290-R360 | мін. R360 |

| Cu-OF | R200-R260 | R240-R300 | R290-R360 | мін. R360 |

| Cu-DLP | R200-R260 | R240-R300 | R290-R360 | мін. R360 |

| Cu-DHP | R200-R260 | R240-R300 | R290-R60 | мін. R360 |

Hardness

| Soft state | Half-hard state | Hard state | Espesially the hard state | |

|---|---|---|---|---|

| Cu-ETP | 40-65 HV | 65-95 HV | 90-110 HV | мін. 110 HV |

| Cu-HCP | 40-65 HV | 65-95 HV | 90-110 HV | мін. 100 HV |

| Cu-FRTP | 40-65 HV | 65-95 HV | 90-110 HV | мін. 110 HV |

| Cu-OF | 40-65 HV | 65-95 HV | 90-110 HV | мін. 110 HV |

| Cu-DLP | 40-65 HV | 65-95 HV | 90-110 HV | мін. 110 HV |

| Cu-DHP | 40-65 HV | 65-95 HV | 90-110 HV | мін. 110 HV |

Would you like to place an order?

Send a request and our manager will contact you soon